Technical

Resources

At Matrix Cooling, we specialize in delivering cooling systems for industrial cooling needs. The solutions we deploy are custom designed and engineered specifically to precisely suite your industrial processes and thermal needs. With one of the best thermal design capabilities in the world, our cooling towers provide you with confidence and peace of mind for all your cooling needs.

What is a Cooling Tower?

A cooling tower is an equipment used to cool water via means of evaporation. Water is one of the most abundant fluids in the world, covering over 70% of the earth surface. A key characteristic of water is its ability to easily and effectively absorb and dispel heat into the atmosphere. Cooling Towers take advantage of this, and through decades of development remains one of the most efficient and cost-effective cooling systems in the world.

In a cooling water system, heat is transferred from a heat source (usually factories, industrial plants or air conditioning systems) via heat exchangers to circulating water. This hot water is channelled to the cooling tower to be cooled.

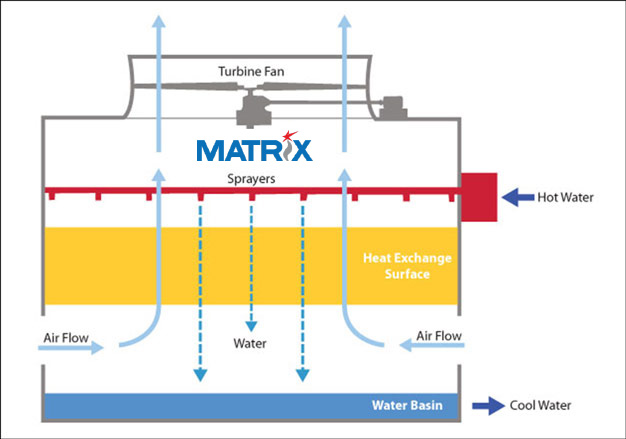

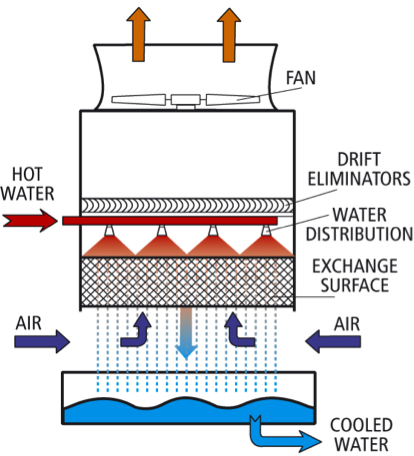

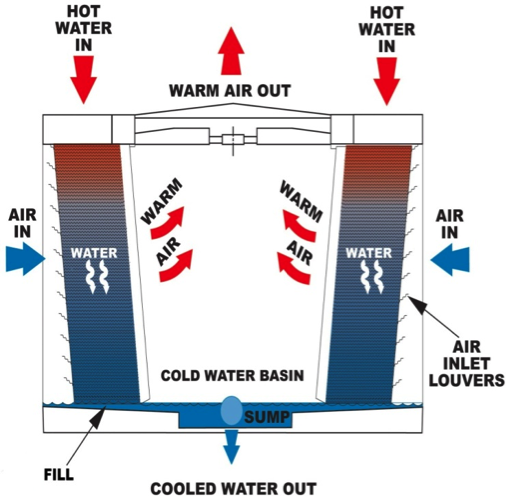

In the cooling tower, the hot water is cooled down via evaporative cooling. Cooling Towers are designed to maximize evaporation of the water by increasing the surface area of the water through a water distribution system (usually sprayers) and a heat exchange surface (called infills). Cold air from the atmosphere is drawn into the cooling tower to pick up the heat and releasing it into the atmosphere.

Counterflow Cooling Tower

In counterflow cooling towers, air enters through the open area below the exchange surface and is drawn up vertically. Air travels vertically across the infill, opposite to the downward motion of the water. Hot Water is sprayed through the water distribution nozzles and flows downward through the infill, opposite to the air flow.

Crossflow Cooling Tower

In crossflow cooling towers, air enters through one or more vertical faces of the cooling tower, and it moves horizontally through the infill sheets. Hot water distributed over the tower by means of orifices in the hot water basin floor. The hot water flow down to the heat exchange surfaces by gravity and the air pass through the water flow into an open plenum chamber.

Concrete Cooling

Towers

Advantages

- Cast in situ or prefab

- High longevity

- Better noise attenuation

- Advantageous in country where concrete price is low

Steel Cooling

Towers

Advantages

- Structurally strong material

- Cost effective material for construction of packaged towers

- Structures can be prefabricated in large sections.

- Different grade of steel can be selected depending on the environment.

Fiberglass Reinforced Plastic

(FRP) Cooling Towers

Advantages

- Light for transportation and construction

- No severe limitations on profile length

- Bracing in one piece

- No limitation in the water quality (any pH)

- Fire protected

AIR INLET: The opening at the lower portion of the tower that allows air to enter.

APPROACH: The difference between the ambient wet bulb temperature and the cold water outlet temperature. This factor is critical in designing the tower.

BLOWDOWN: The water discharged from the system to control concentration of chemicals and minerals in the circulating water.

COLD WATER BASIN: In a wet tower the basin is the channel under the tower that receives the called water and directs its flow to the suction line or pump.

COUNTERFLOW TOWER: A tower in which the air flows upwards upward through the fill material and interfaces countercurrently with the falling heated water.

CROSSFLOW: A tower in which the air flows horizontally across the fill material and interfaces perpendicularly with the falling heated water.

DRIFT: Water lost by the tower as liquid droplets entrained in the exhaust air.

DRY BULB: The temperature of the inlet or ambient air adjacent to the cooling tower as measured by a dry-bulb thermometer.

DRY HEAT EXCHANGER: A cooling system that employs a series of tubes of either metal or thermoplastic material through which the heated water circulates to become cool.

DRY/WET TOWER: A dry heat exchanger system combined with an evaporative cooling tower that is used to reduce the make-up water requirement.

EVAPORATION RATE: Water evaporated from the circulating water by the cooling process. Evaporated water is pure water, whereas drift has the same chemicals concentration as the circulating water.

EXHAUST AIR: The mixture of air and its associated vapor, discharged from the tower.

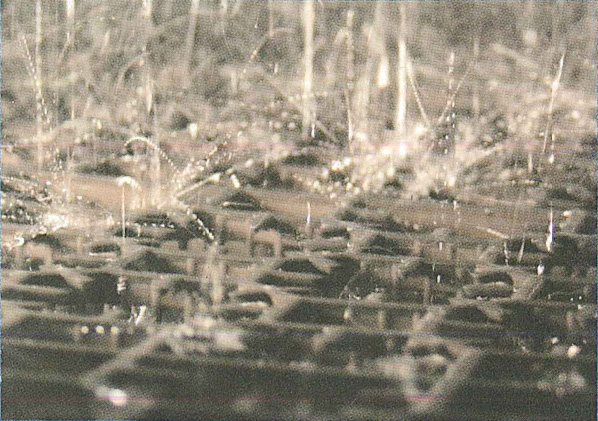

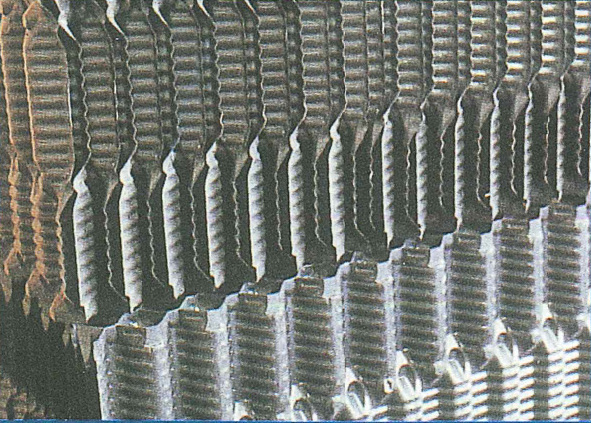

FILL: The medium in a wet cooling tower that aids in the heat exchange process. The fill provides the surface area over which the heated water is sprayed. The fill effects the heat and mass transfer between the water and circulating air into the tower.

- Film Fill- the thermoplastic fill produced in a modular honeycomb design.

- Splash Fill- injection molded or extruded thermoplastic splash fill in a multi-tiered design.

MAKE-UP WATER: Water added to the circulating water system to replace water lost from the system by evaporation, drift, blowdown and leakage.

MECHANICAL DRAFT COOLING TOWER: A tower in which the air movement is effected by one or more fans.

- Induced Draft- fans are situated at the air exhaust.

- Forced Draft- fans are situated at the air inlet.

NATURAL DRAFT COOLING TOWER: A tower in which the air movement depends upon the difference in density between the ambient air surrounding the tower and the internal air. This tower typically finds application in systems cooling more than 200,000 GPM (gallons per minute) of water but has been used in applications as low as 60,000 GPM.

PLUME: The visible vapor exhaust from a cooling tower.

RANGE: The temperature difference between the inlet hot water temperature and the outlet cold water temperature. This value, combined with the flow, determines the heat load the tower must remove.

WET BULB: The temperature of the inlet or ambient air adjacent to the cooling tower as measured by a psychrometer. Also known as the thermodynamic wet-bulb temperature or the temperature of adiabatic saturation. This is the theoretical cooling limit of a wet cooling tower.

WET/ DRY TOWER: An evaporative cooling tower combined with a dry heat exchanger system, used to reduce or abate cooling tower plume during cold weather operation.

Matrix has wide range of heat transfer media suitable for:

- Any industrial water

- Sea water

- Low pH solution

- TSE (treated sewage effluent)

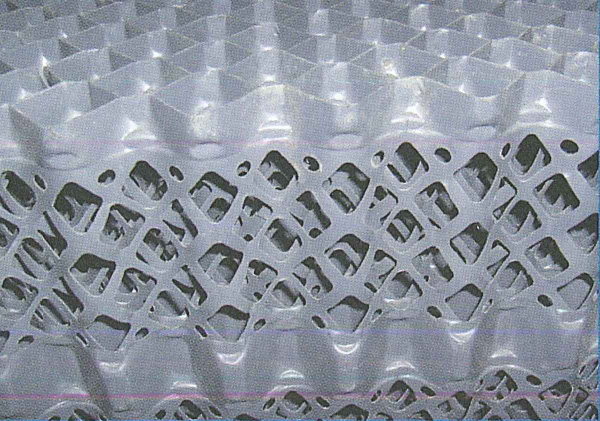

The GOLDENGRIDS, the real splash fill, is the all purpose solution suitable for most qualities, including sea water and heavily contaminated water. This heat transfer media consists of trays hung from beams located above the water distribution. The grids, their supports and spacers ate made of polypropylene; the wires according to the water aggressiveness are in SS316 or in a more exotic alloy.

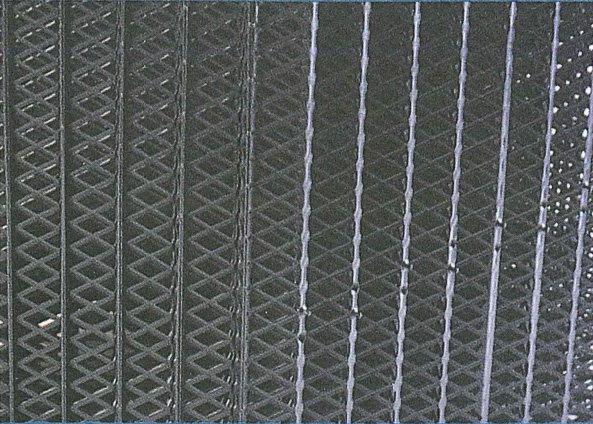

The TRICKLEFILL offers what is probably the highest resistance to scaling and fouling worldwide. Using Hamon’s well proven technology of non-contact sheets, this vertical core fill is designed with wide sheet spacing. The sheets are smooth and incorporate a number of large square holes. The holes induce beneficial turbulence for heat transfer, whilst no fouling or scaling occurs on the supports.

The strips (resulting from perforation) make this pack act party like a grid type. Therefore it is an excellent alternative to “mesh” or “3D grids”. It can be produced PVC and PP.

The MESH type fill combines splash and film heat exchange process with the advantages of low fouling capability of the splash fill and the good thermal efficiency of the film fill. It is well adapted to any induced or natural draft cooling tower using poor industrial water quality. Water with high concentrations of suspended fibres is not recommended.

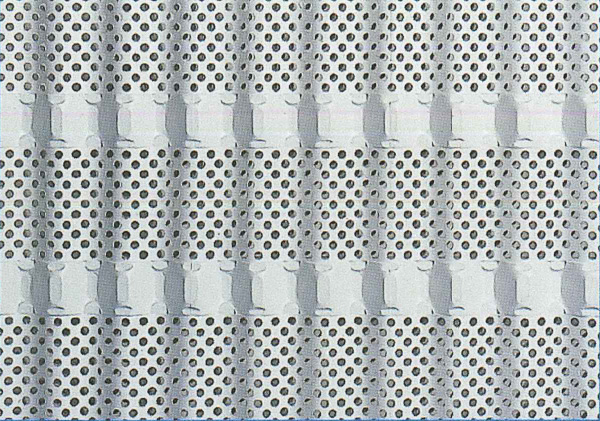

The COOLFREE is the most advanced film fill combining low-fouling and low scaling properties whilst retaining good thermal performance. The main application is for cooling towers using very poor water quality, in some cases even without water treatment. It is also very good for film fill cross-flow cooling towers.

The CLEANFLOW film fill has been qualified worldwide as the best film fill combining low fouling properties with good thermal performance. It is well adapted to any induced draft or natural draft cooling tower using poor quality industrial water. It is also suitable for other severe applications such as laminated decanting and gas cleaning.

The CLEANFLOW PLUS is the improved technology of the cleanflow fill by increasing its thermal performance whilst retaining its fouling resistance. It is well adapted to any induced or natural draft cooling tower using poor industrial water quality, in particular sea water.

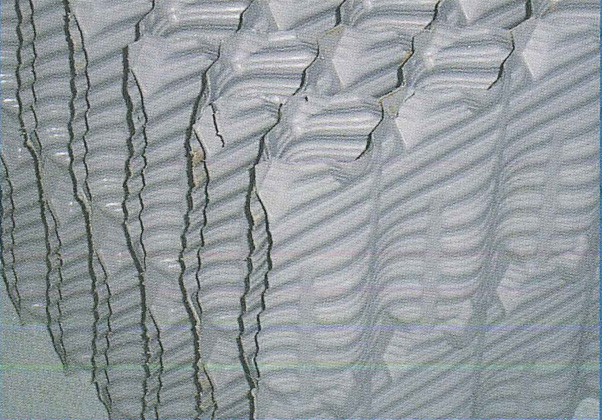

The COOLFILM is probably the most thermally efficient fill worldwide. It is well adapted to any induced draft or natural draft cooling tower using normal industrial water quality.